Industrial Makerspace Landsberg

How might we create a space that can encourage know-how exchange among learning organisations?

Industrial Makerspace Landsberg is a shared facility for up to 100 innovators, with a particular focus on the digital chain. Tailored for industrial and commercial companies, innovators and startups, space offers future-proofed work areas with state-of-the-art technical infrastructure as well as workshops, inspirational talk series, and innovation consulting services. ATÖLYE has contributed to the project in the business design of the venture, it’s business development efforts, shaping of its brand and vision as well as its content and product offerings.

Project Team:

Begüm Ural, Berna Erenoğlu, Engin Ayaz, Nesile Yalçın, Ufuk Barış Mutlu, Kerem Alper

Project Lead:

Engin Ayaz, Nesile Yalçın

Network:

Architekturbüro Edgar Bürger (Core + Shell Architecture), Wurm + Henningsen PartG mbB (Static), Duschl Ingenieure GmbH & Co KG (Mechanical), Ingenieurbüro für Brandschutz IB Kade (Fire), Konstruktionsgruppe Bauen AG (Energy Efficiency), E-WALD GmbH (Electronics), Andrea T. Schaffner-Dittler, Christine Rittinghausen (Cafeteria Design)

Early in 2016, we engaged for the strategy and business design of the venture, it’s business development efforts, shaping of its brand and vision as well as its content and product offerings. This was followed by architectural concept consulting for interiors and furniture manufacturing in the following years. Here, ATÖLYE’s know-how beyond a typical design office on ‘running’ such a space in Istanbul as a creative hub contributed greatly to establishing a robust strategy for Industrial Makerspace.

The Industrial Makerspace is far different than its urban counterparts. By focusing on the semi-rural hinterland of Germany with deep industrial heritage and technical prowess, the project offers a shared collaboration ground for innovative German companies across multiple sectors such as automotive manufacturing, robotics, 3D printing, kitchen equipment, aeronautics, and more.

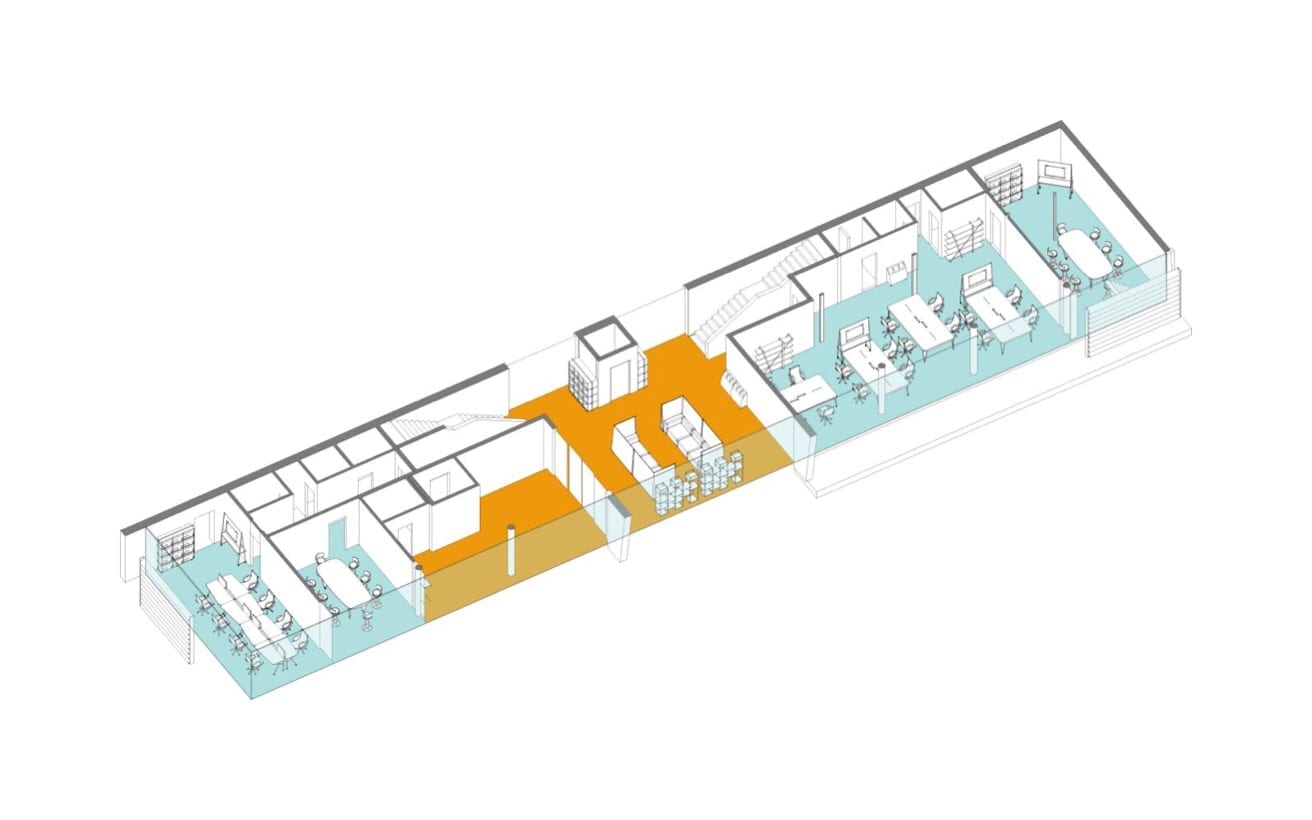

The flexible and dynamic space serves as a magnet for young changemakers along with experienced doers in these companies, while offering a public-facing window for rather introvert R&D teams to better test their prototypes and new ideas. Split into two construction phases with a total of more than 4.000 m² of gross floor area, 2.500 m² is dedicated to industrial hall space and 1,500 m² to office and event spaces.

From a design standpoint, ATÖLYE’s interiors concept focused on developing custom workspace furniture via CNVS, its furniture line for the workspaces, and using scaffolding as a box-in-a-box design pattern for the ‘hall space’ to enable maximum customization. More than 20 models from the CNVS furniture line were either customized or designed from scratch to accommodate the needs of the space, ranging from vertical separators to tables, from sofas to lighting devices.

Alongside its design engagement, ATÖLYE also focused on furniture manufacturing for more than 150 items, all of which were fabricated in Turkey using ecological materials such as FSC-certified plywood and recycled OSB. Along with individual furniture pieces, ATÖLYE also developed a “CNVS Playbook” outlining all workspace combinations for the tables to be experimented with by the tenants, thus focusing on the user experience at post-occupancy phase as well.

These items are combined with an inviting entrance foyer area, which reshuffles itself from an informal lounge area to an event space for more than 80 people using modular furniture on wheels. ATÖLYE’s proposal also included a kinetic sculpture that would be part of the lighting design scheme at the entrance, using small weights that would reflect the activity inside via their circular movement inspired by Foucault’s Pendulum.

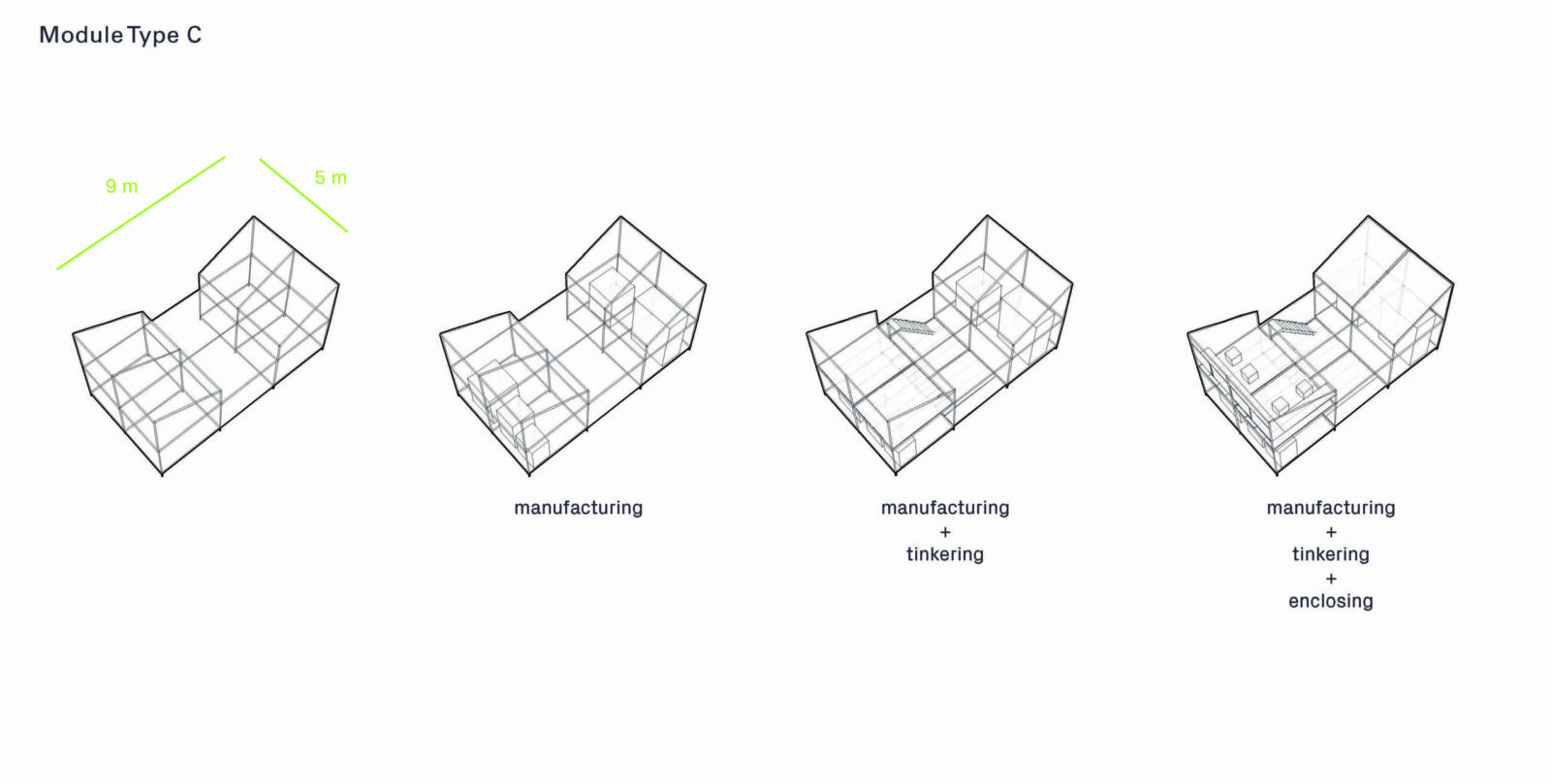

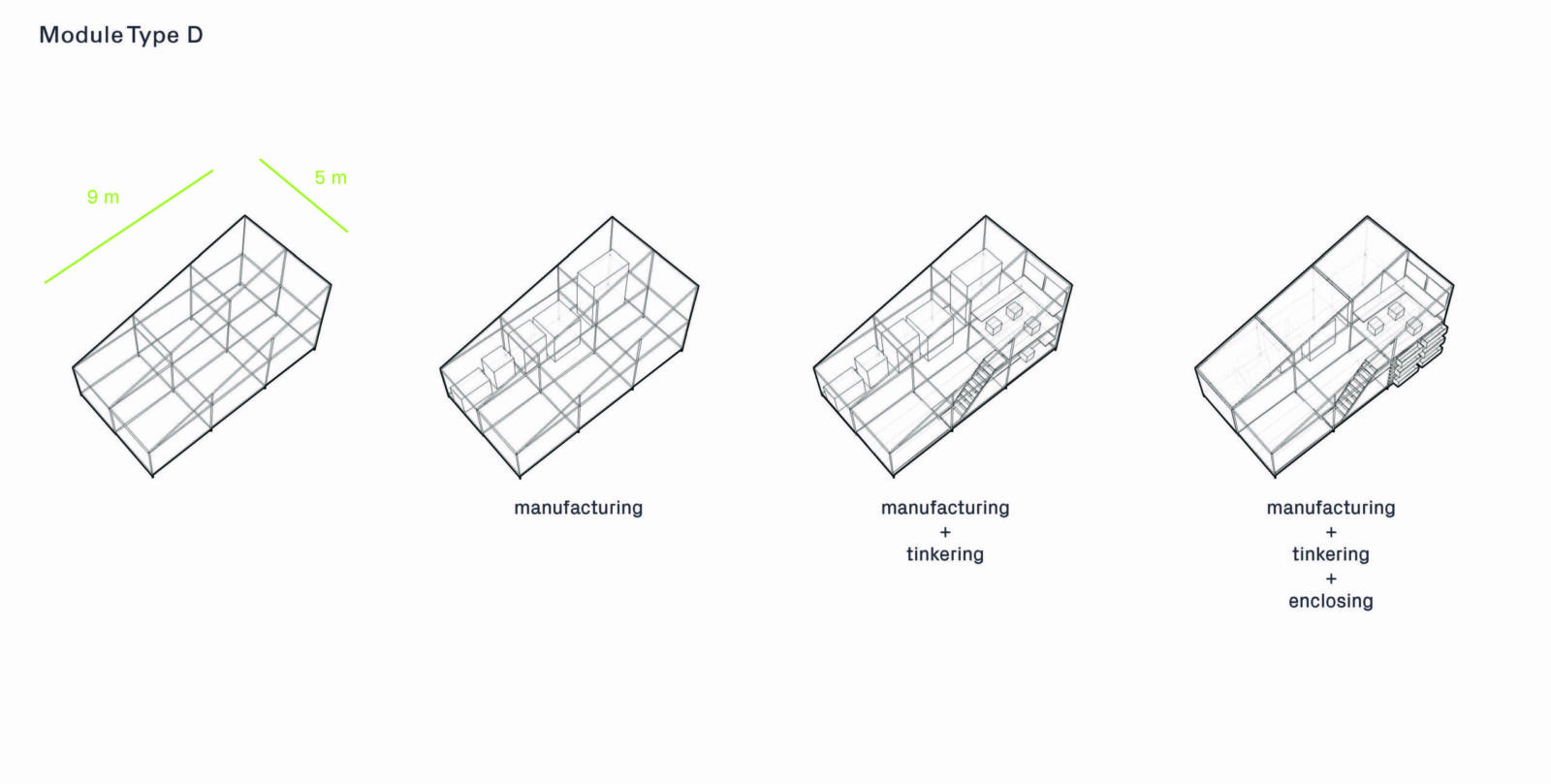

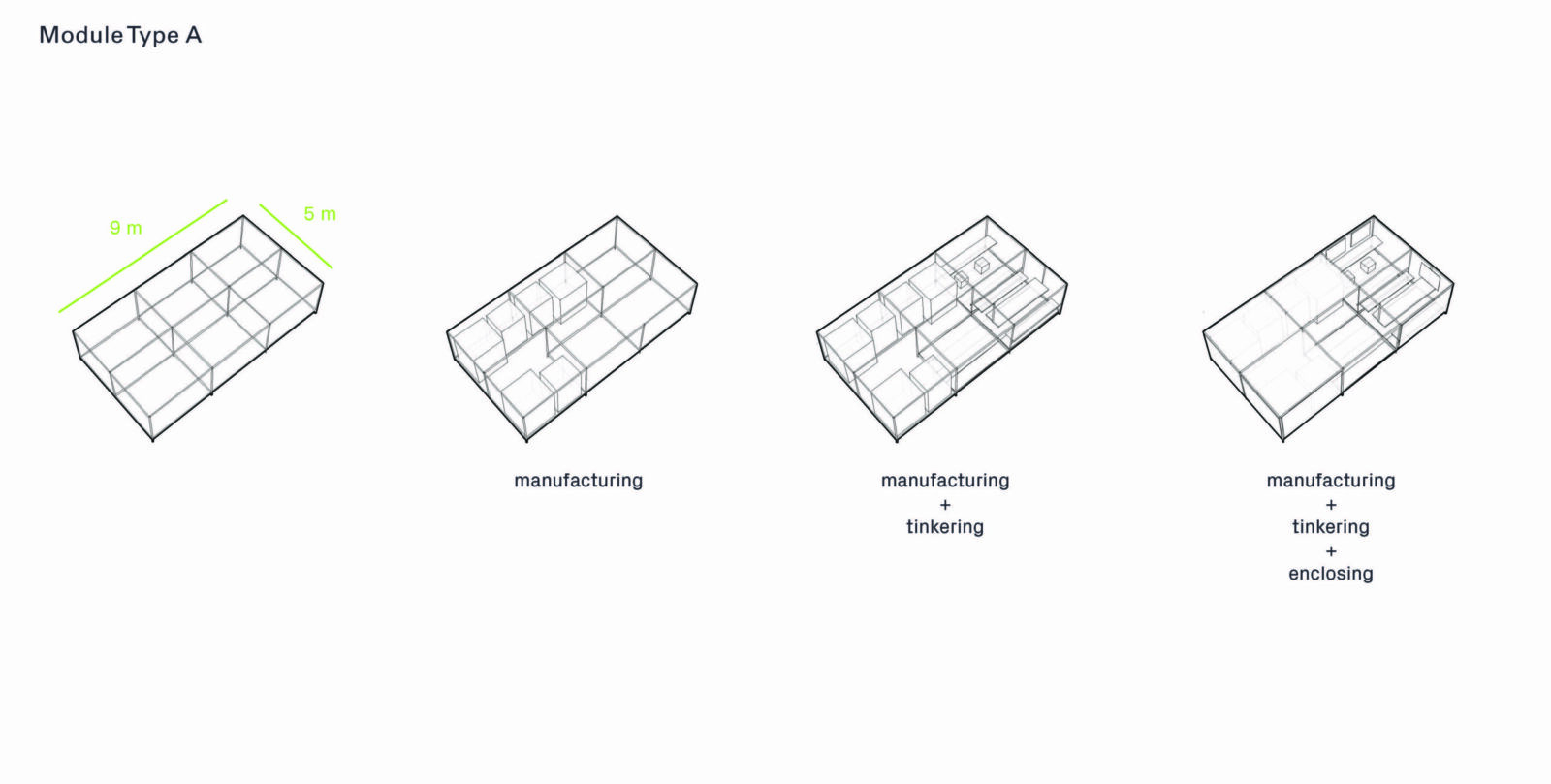

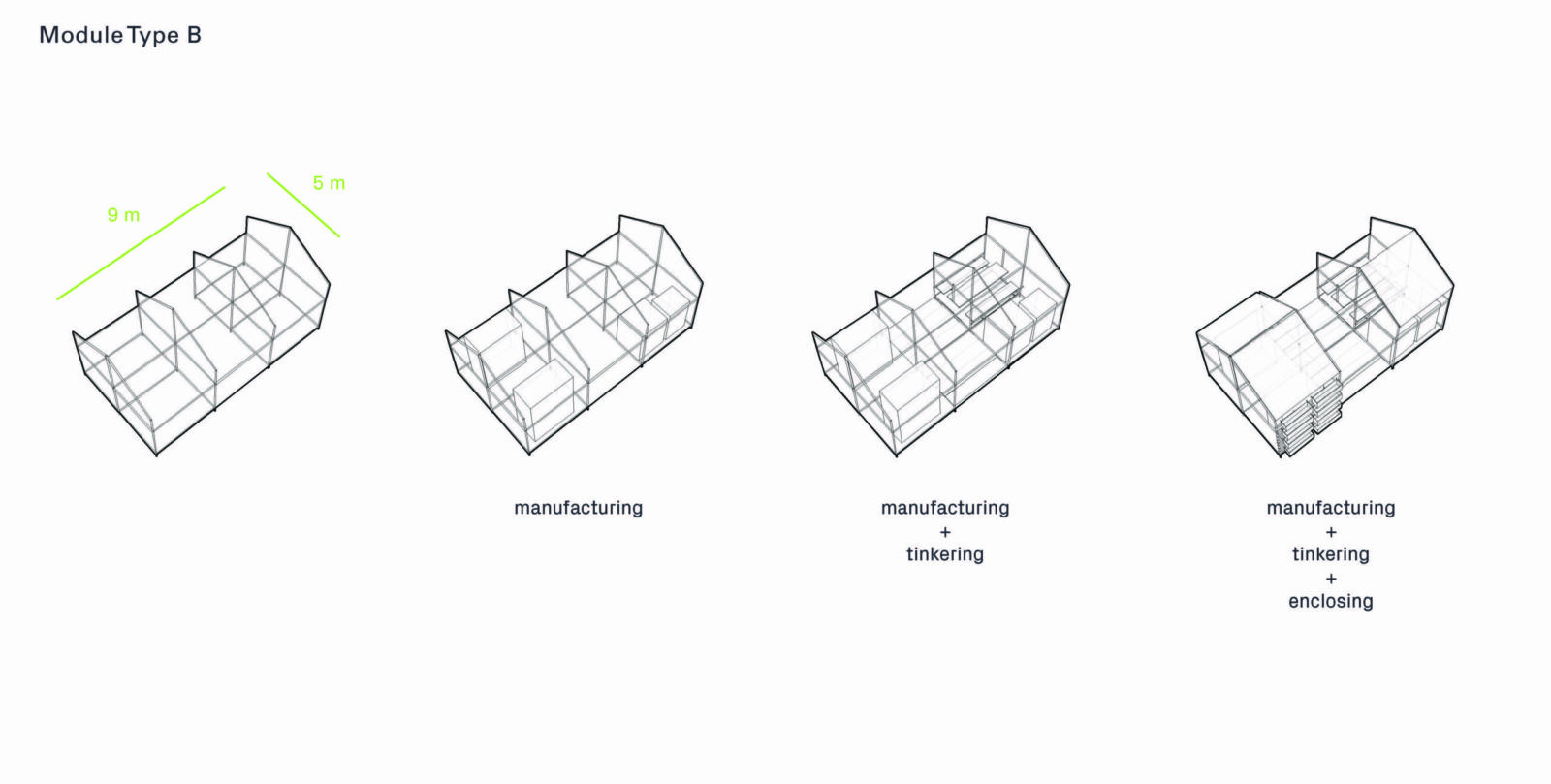

On the hall space, the design focus shifts itself from developing furniture- and lighting-scale solutions to more spatial arrangements via scaffolding units. By developing a basic 2.4×3 meter grid on the floor, the scaffolding pieces can easily be bolted on the ground and offer rentable areas for manufacturing, tinkering and enclosing. Taking the business requirements as an input, the design scheme also offered a curtain system to shrink the open space for the early rental period of the facility and to customize it for the needs of future tenants.

In this project, ATÖLYE’s design ideas were implemented only partially, due to multiple factors such as time limitations, budget constraints and technical requirements for the halle space. After the concept development phase for the interiors, a large interdisciplinary team based in Germany continued with the project across design development and construction phases, leading the way for public opening in November 2018. The resulting project is outstanding in its technical specifications, such as 50% energy efficiency performance, air conditioning via activated floors and ceilings and 200+ kw solar paneling, among others.

Looking forward, the Industrial Makerspace project with its unique product offering is likely to expand across Germany in other sites in coming years. As project needs evolve, ATÖLYE as a strategic design studio, is likely to offer various strategy and design solutions across scales, be it digital design, new furniture development or service design.